We are committed to providing the most comprehensive and competitive automotive suspension system solutions for global buyers. Whether it’s Japanese, German, American or Korean models, we have complete mold development capabilities and a massive inventory of spot goods. From factory standard replacement parts to high-performance modified parts for improved handling, you can find matching products here and easily achieve one-stop bulk procurement.

Excellent shock absorbers suitable for mainstream global car models

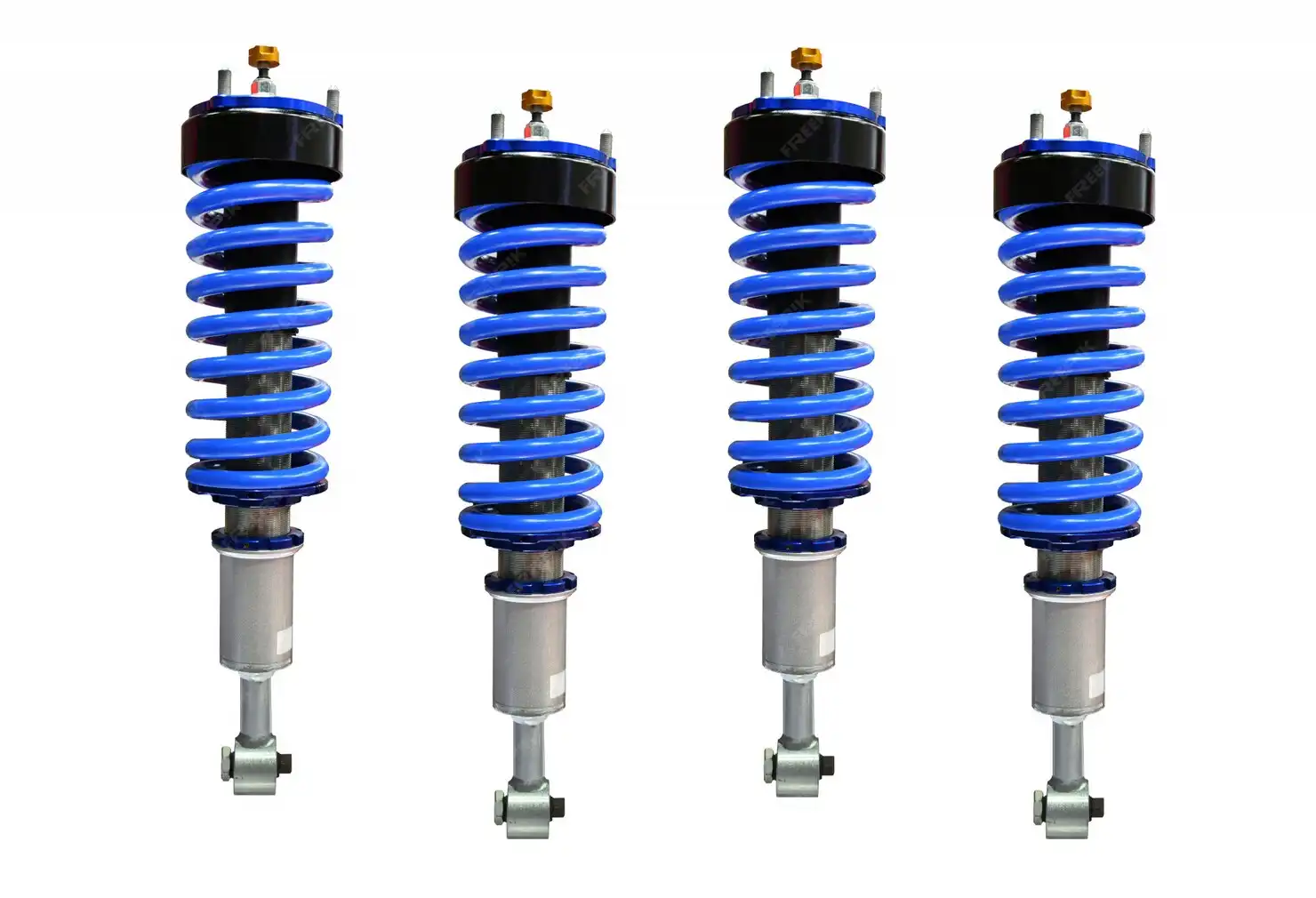

In terms of craftsmanship, we adopt high-precision chrome plated piston rods, Japanese NOK oil seals, and fully automatic double-layer welding technology to comprehensively improve the sealing and pressure resistance of shock absorbers; In terms of product coverage, we offer a variety of structures including MacPherson, double wishbone, and air suspension to accurately match the needs of sedans, SUVs, and pickups; In terms of quality control, all products have undergone 3 million cycles of fatigue testing and 72 hours of salt spray testing to ensure 100% non-destructive installation and original factory quality, which is a solid support for expanding your automotive parts market.

Excellent durable craftsmanship

Our shock absorbers are made of high-strength steel, and each shock absorber must undergo 3 million cycles of fatigue testing and 72 hours of salt spray testing before leaving the factory. This uncompromising approach to quality provides you with an extremely reliable and low repair rate solution

1: 1. Accurate factory replication

Strictly following OEM factory specifications for design, our shock absorbers ensure a perfect match with the corresponding vehicle models, achieving true “plug and play” non-destructive installation without any modification. Through precise tuning of the damping valve system, it can effectively filter out road bumps

Massive SKU reserve

We have the most extensive product database in the industry, covering mainstream Japanese, German, American, Korean, and domestic car models, with over 5000 SKUs and continuously updated new product development capabilities. Whether you need regular accessories for popular car models or specific models for niche models, we can provide comprehensive solutions

Efficient supply chain system

We have a product warehouse of over 10000 square meters and maintain sufficient finished product reserves throughout the year to ensure the supply of hot selling models in stock. We can achieve fast sorting and shipping for both small batch trial orders and full container bulk purchases

Purchase high-quality shock absorbers

To ensure accuracy and efficiency in every transaction, we have established a transparent B2B cooperation workflow. We understand that precision is key in the auto parts industry. Whether you are placing a trial order or a container-load purchase, our standardized process guarantees that you receive the exact shock absorbers you need, on time and within budget.

How to Source: From Inquiry to Delivery

We can create recyclable single material packaging thanks to our processing technology, which is an important capability that shouldn’t be overlooked.

Step 1: Submit Inquiry

Send us your requirements, including OE numbers, car models, or drawings. The more details you provide, the faster we can respond.

Step 2: Professional Quotation

Our team analyzes your needs and provides a competitive quotation within 24 hours, including FOB prices, MOQ, and estimated lead time.

Step 3: Sample Verification

Before mass production, we encourage ordering samples. Test our fitment and damping performance to ensure they meet your local market standards.

Step 4: Order & Production

Upon confirmation and deposit, we launch manufacturing. We support OEM branding and custom packaging to enhance your brand identity.

Step 5: Quality Control

Every batch undergoes rigorous inspection (dimensions, leakage, and fatigue tests) before leaving our warehouse to ensure zero defects.

Step 6: Logistics & Support

We handle export documentation and shipping arrangements. Our after-sales team remains available to assist with any technical or warranty inquiries.

Our high-quality choices vs. general market products

Adopting high-precision chrome plated piston rod, combined with fully automatic double-layer welding process. Through 3 million fatigue tests, we ensure zero leakage and an ultra long lifespan, helping you completely avoid after-sales troubles.

Often built with recycled rubber seals and rough rods using manual welding. Prone to early leakage, noise, and snapping. High return rates can severely damage your business reputation.

Customer reviews

generally, our MOQ is 50 pieces per model. However, we understand the need to test the market, so we accept smaller trial orders or mixed-container orders for new partners. Please contact our sales team for a flexible solution.

Yes, absolutely. We specialize in private labeling. We can laser engrave your logo on the shock absorber body, print your brand on the packaging box, and even customize the color finish according to your design requirements.

The most accurate way is to send us a list of OE Numbers (Original Equipment Numbers) or KYB/Monroe part numbers along with your estimated quantity. We will provide a detailed FOB price list within 24 hours.

Our factory is certified under ISO/TS 16949 quality management systems. Every product undergoes strict quality control, including a 3-million-cycle fatigue test and salt spray testing to ensure durability and safety.

For items in stock, we can ship within 3-7 days. For mass production orders, the lead time is typically 30-45 days after receiving the deposit, depending on the order volume.